摘 要

由于挥发性有机化合物(VOCs)对人体健康的长期负面影响以及环境立法的严格要求,溶剂型油墨的使用受到了越来越多的限制.为了避免挥发性有机化合物的产生,水作为一种环保、廉价的溶剂受到越来越多研究者的青睐.至此,水性油墨应运而生.水性油墨一般由连接料、颜料、助剂和水组成.其中水性树脂连接料被称为油墨的"心脏",决定着油墨性能的好坏.目前水性聚氨酯作为油墨连接料得到人们的广泛关注,其中磺酸型水性聚氨酯(SWPU)更容易制得粘度较低,固含量高的乳液,同时其耐酸碱性、耐热性、耐水性和对基材的粘结强度都有了很大的提高,具有良好的经济价值和市场前景.本文以磺酸盐型水性聚氨酯为水性油墨连接料,并引入荧光单体,以期合成一种用于塑料包装薄膜上的磺酸型水性聚氨酯荧光防伪油墨.

第一章主要对水性油墨、水性聚氨酯、磺酸盐水性聚氨酯及荧光水性聚氨酯进行了简单的介绍.

第二章以异佛尔酮二异氰酸酯、1,4-丁二醇和乙二胺基磺酸钠(A95)作为硬段,聚己二酸新戊二醇酯二醇(PNA)和聚己二酸-1,4-丁二醇酯二醇(PBA)为混合软段,合成了一系列磺酸型水性聚氨酯,探讨了不同 PNA 与 PBA 质量比对聚氨酯乳液及其胶膜性能的影响.采用 FTIR 表征了 WPU 的结构.结果表明,SWPU 乳液具备良好的粒径分布和贮存稳定性,随着多元醇中 PNA占比的增加,SWPU 胶膜的结晶性和拉伸强度不断降低,断裂伸长率不断增加,吸水率先减小后增加,而水接触角则先增大后减小;SWPU 乳液在 BOPP 薄膜上的 T-型剥离强度先增大后减小,热稳定性差别不大.当 PNA 占多元醇的质量分数为 40%时,SWPU 的综合性能最佳,此时,SWPU 的 T-型剥离强度为 5.0N/25mm,24h 吸水率为 3.95%,水接触角为 75°,拉伸强度和断裂伸长率分别为 33.89MPa 和737.8%.

第三章以聚己二酸新戊二醇酯二醇(PNA)和聚己二酸-1,4-丁二醇酯二醇(PBA)2∶3 的质量比为混合软段,通过改变功能性荧光扩链剂 N,N-二羟乙基苯胺-γ-三联吡啶(TPPDA)的含量合成了一系列磺酸型水性荧光聚氨酯乳液,并采用 FTIR 测试了荧光水性聚氨酯(FWPU)结构.结果表明,FWPU 乳液具备良好的粒径分布和贮存稳定性,随着 TPPDA 含量的增加,FWPU 的拉伸强度不断增加,而断裂伸长率、24h 吸水率和结晶性能不断减小,热稳定性略有增加,T-型剥离强度略微减小.光学性能测试结果表明,荧光单体 TPPDA 的紫外最大吸收峰 λmax 于为 370 nm,而 FWPU 的紫外最大吸收峰 λmax 为 360 nm, 随着TPPDA 含量的增加,紫外吸收峰的强度增大,荧光强度先增加后减小.当 TPPDA质量分数为 0.4%时,FWPU 胶膜荧光强度达到最大,此时,FWPU 的 T-型剥离强度为4.8N/25mm,24h吸水率为3.11%,拉伸强度和断裂伸长率分别为41.73MPa和 682.4%,水性聚氨酯综合性能最佳.

本文第四章用磺酸盐型水性荧光聚氨酯为油墨连接料,选择了钛白粉为颜料制备了一系列颜基比不同的白色油墨,并对油墨的性能进行了研究.实验结果表明,随着颜基比的增加,水性荧光油墨的细度、粒径、黏度和初干性都不断增加,而光泽度不断减小.附着牢度和耐水性随颜基比增加呈现不断变差的趋势,水性荧光油墨都具有较好的抗黏连性.当颜基比为 1∶2 时,水性荧光的综合性能最佳,此时,水性荧光油墨的粘度为 217.6 mPa·s,光泽度 28.6% ,初干性 19mm/30s,细度和粒径分别为 10μm 和 14.12nm,同时油墨具有较好的耐水性、附着牢度、抗黏连性和荧光强度.

关键词:水性油墨,磺酸型水性聚氨酯,荧光,防伪

Abstract

Due to the long-term negative effects of volatile organic compounds (VOCs) onhuman health and the strict requirements of environmental legislation, the use ofsolvent inks has been increasingly restricted.In order to avoid the production ofvolatile organic compounds (vocs), water as an environmentally friendly and cheapsolvent has been favored by more and more researchers.Thus, water-based inkemerged. Water-based inks generally consist of binders, pigments, additives and water.Among them, the water-based resin binder is called the "heart" of the ink, whichdetermines the performance of the ink. At present, waterborne polyurethane as inkbinder has been widely concerned by people, among which, sulfonated waterbornepolyurethane (SWPU) is easier to produce low viscosity, high solid content emulsion,at the same time, its acid and alkali resistance, heat resistance, water resistance andthe bonding strength of the substrate have been greatly improved, has a goodeconomic value and market prospects.In this paper, the sulfonate waterbornepolyurethane is used as the connection material of waterborne ink, and the fluorescentmonomer is introduced to synthesize a kind of sulfonate waterborne polyurethanefluorescent anti-counterfeit ink for plastic packaging films.

The first chapter mainly introduces water-based inks, waterborne polyurethanes,sulfonate waterborne polyurethanes, and waterborne fluorescent polyurethanes.

The second chapter uses isophorone diisocyanate, 1, 4-butylene glycol ethyl andsodium ethylenediamine sulfonate (A95) as hard segment, gather adipic acidneopentyl glycol ester diol (PNA) and poly (adipic acid-1, 4-butanediol ester diol(PBA) as mixed soft segments, a series of sulfonic acid type waterborne polyurethaneemulsion was synthesized.The effects of different mass ratios of PNA and PBA on theproperties of polyurethane emulsions and their films were discussed.The structure ofWPU was characterized by FTIR. The results showed that SWPU emulsion had goodparticle size distribution and storage stability. With the increase of PNA in polyols, thecrystallinity and tensile strength of WPU film decreased, elongation at break increased, water absorption first decreased and then increased, while water contactAngle first increased and then decreased.The T-peel strength of SWPU emulsion onBOPP film increased first and then decreased, with little difference in thermalstability.When the mass fraction of PNA in polyols is 40%, the comprehensiveperformance of SWPU is the best. At this point, the T-peel strength of SWPU is5.0N/25mm, the water absorption rate at 24h is 3.95%, the water contact Angle is 75°,and the tensile strength and elongation at break are 33.89MPa and 737.8%.

In the third chapter, the mass ratio of 2: 3 of neopentyl glycol adipate and poly(1,4-butanediol adipate) (PBA) is used as the mixed soft segment. A series of sulfonicacid water-based fluorescent polyurethane emulsions were synthesized by the contentof functional fluorescent chain extender N,N-dihydroxyethylaniline-γ-terpyridine(TPPDA), and the structure of FWPU was tested by FTIR. The results show that theFWPU emulsion has good particle size distribution and storage stability. With theincrease of TPPDA content, the tensile strength of FWPU increases continuously,while the elongation at break, water absorption at 24h and crystallization propertydecrease continuously, the thermal stability increases slightly, and the t-peel strengthdecreases slightly. The optical performance test results show that the UV maximumabsorption peak λmax of the fluorescent monomer TPPDA is 370 nm, and the UVmaximum absorption peak λmax of the FWPU is 360 nm. As the content of TPPDAincreases, the intensity of the UV absorption peak increases, and the fluorescenceintensity Increase first and then decrease. When the TPPDA mass fraction is 0.4%, thefluorescence intensity of the FWPU film reaches the maximum. At this time, theT-type peel strength of the FWPU is 4.8N / 25mm, and the water absorption rate at24h is 3.11%. The tensile strength and elongation at break are respectively 41.73MPaand 682.4%, the comprehensive performance of water-based polyurethane is the best.

In the fourth chapter of this paper, a series of white inks with differentpigment-base ratios were prepared by using sulfonate-based water-based fluorescentpolyurethane as the ink binder, and titanium dioxide was selected as pigment. Theexperimental results show that with the increase of the pigment-base ratio, thefineness, particle size, viscosity, and initial drying of water-based fluorescent inks are constantly increasing, while the gloss is continuously decreasing. Adhesion fastnessand water resistance tend to worsen with the increase of pigment-base ratio. Water-based fluorescent inks have better anti-blocking properties. When thepigment-base ratio is 1: 2, the overall performance of water-based fluorescence is thebest. At this time, the viscosity of the water-based fluorescent ink is 217.6 mPa · s, thegloss is 28.6%, and the initial dryness is 19mm/30s. The fineness and particle size are respectively It is 10 μm and 14.12 nm. At the same time, the ink hasgood water resistance, fastness to adhesion, anti-blocking and fluorescence intensity.

Key words: Water-based ink, The sulfonate waterborne polyurethane, Fluorescence, Anti-counterfeit

目 录

第一章 绪论 .................................................................................................................................1

1.1 引言...................................................................................................................................1

1.2 水性油墨概述 ................................................................................................................1

1.2.1 水性油墨的组成......................................................................................................2

1.2.2 水性油墨连接料树脂的研究状况..........................................................................3

1.3 水性聚氨酯概述............................................................................................................4

1.3.1 水性聚氨酯的制备方法..........................................................................................5

1.3.2 水性聚氨酯的改性..................................................................................................6

1.4 磺酸盐水性聚氨酯概述............................................................................................10

1.4.1 硬段含磺酸盐型 WPU..........................................................................................11

1.4.2 软段含磺酸盐型 WPU..........................................................................................11

1.5 荧光聚氨酯简介..........................................................................................................12

1.5.1 荧光发光机理........................................................................................................12

1.5.2 荧光聚氨酯材料....................................................................................................13

1.6 论文研究意义和主要内容........................................................................................13

1.6.1 研究意义................................................................................................................14

1.6.2 研究内容................................................................................................................15

第二章 磺酸盐水性聚氨酯油墨连接料的制备与性能..................................................16

2.1 引言.................................................................................................................................15

2.2 实验部分 .......................................................................................................................17

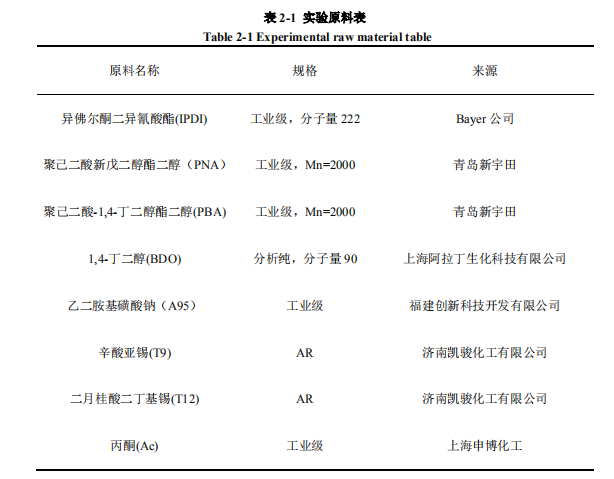

2.2.1 实验原料................................................................................................................17

2.2.2 SWPU 乳液的合成................................................................................................17

2.2.3 SWPU 胶膜的制备................................................................................................19

2.3 性能测试与表征..........................................................................................................19

2.3.1 乳液粒径测试........................................................................................................19

2.3.2 乳液稳定性测试....................................................................................................19

2.3.3 乳液固含量测定...................................................................................................20

2.3.4 乳液粘度测试........................................................................................................20

2.3.5 傅里叶变换红外光谱( FTIR) 测试......................................................................20

2.3.6 拉伸强度测试........................................................................................................20

2.3.7 热重分析(TGA)测试........................................................................................20

2.3.8 水接触角测试........................................................................................................20

2.3.9 吸水率测试...........................................................................................................21

2.3.10 T-型剥离强度测试 ..............................................................................................21

2.3.11 X-射线衍射(XRD)测试 .................................................................................21

2.4 结果与讨论...................................................................................................................21

2.4.1 SWPUs 胶膜的红外分析......................................................................................21

2.4.2 SWPUs 乳液性能分析..........................................................................................22

2.4.3 SWPUs 胶膜 XRD 分析........................................................................................23

2.4.4 SWPUs 乳液 T-型剥离强度测试..........................................................................24

2.4.5 SWPUs 胶膜吸水率及水接触角分析 ..................................................................24

2.4.6 SWPUs 胶膜热稳定性分析..................................................................................25

2.4.7 SWPUs 胶膜力学性能分析..................................................................................27

2.5 本章小节 ......................................................................................................................28

第三章 基于 N,N-二羟乙基苯胺-γ-三联吡啶的磺酸型水性荧光聚氨酯的合成及

性能 ...............................................................................................................................................29

3.1 引言.................................................................................................................................29

3.2 实验部分 .......................................................................................................................30

3.2.1 实验原料................................................................................................................30

3.2.2 FWPU 乳液的合成................................................................................................31

3.2.3 FWPU 胶膜的制备................................................................................................32

3.3 性能测试与表征..........................................................................................................32

3.3.1 乳液粒径测试........................................................................................................33

3.3.2 乳液稳定性测试....................................................................................................33

3.3.3 乳液固含量测定...................................................................................................33

3.3.4 乳液粘度测试........................................................................................................33

3.3.5 傅里叶变换红外光谱( FTIR) 测试......................................................................33

3.3.6 WPU 紫外-可见吸收(UV-Vis)光谱的测定.....................................................34

3.3.7 WPU 荧光光谱测定..............................................................................................34

3.3.8 拉伸强度测试........................................................................................................34

3.3.9 热重分析(TGA)测试........................................................................................34

3.3.10 吸水率测试.........................................................................................................34

3.3.11 T-型剥离强度测试...............................................................................................35

3.3.12 X-射线衍射(XRD)测试.................................................................................35

3.4 结果与讨论...................................................................................................................35

3.4.1 FWPU 胶膜的红外分析........................................................................................35

3.4.2 FWPU 乳液性能分析............................................................................................36

3.4.3 光学性能分析........................................................................................................37

3.4.4 FWPU 乳液 T-型剥离强度测试 ...........................................................................39

3.4.5 FWPU 胶膜吸水率分析........................................................................................40

3.4.6 FWPU 胶膜热稳定性分析....................................................................................41

3.4.7 FWPU 胶膜 XRD 分析 .........................................................................................41

3.4.8 FWPU 胶膜力学性能分析....................................................................................42

3.5 本章小结 .......................................................................................................................43

第四章 磺酸型水性荧光聚氨酯油墨的配制及性能研究..............................................45

4.1 引言.................................................................................................................................45

4.2 实验部分 .......................................................................................................................45

4.2.1 实验原料................................................................................................................45

4.2.2 水性油墨的配制....................................................................................................46

4.2.3 水性油墨制样.......................................................................................................47

4.3 性能测试与表征..........................................................................................................47

4.3.1 颜色........................................................................................................................48

4.3.2 细度........................................................................................................................48

4.3.3 粒径........................................................................................................................48

4.3.4 粘度.......................................................................................................................48

4.3.5 初干性....................................................................................................................48

4.3.6 光泽度....................................................................................................................48

4.3.7 附着牢度................................................................................................................48

4.3.8 抗粘连性................................................................................................................49

4.3.9 耐水性....................................................................................................................49

4.3 结果与讨论...................................................................................................................49

4.3.1 水性油墨的颜色分析............................................................................................50

4.3.2 水性油墨的细度及粒径分析................................................................................50

4.3.3 水性油墨的黏度分析...........................................................................................51

4.3.4 水性油墨的光泽度分析.......................................................................................52

4.3.5 水性油墨的初干性分析.......................................................................................52

4.3.6 水性油墨的附着牢度分析...................................................................................53

4.3.7 水性油墨的耐水性分析........................................................................................53

4.3.8 水性油墨的抗粘连性分析...................................................................................53

4.3.9 水性油墨荧光性能分析........................................................................................53

4.4 本章小结 .......................................................................................................................54

结论 ...............................................................................................................................................56

参考文献......................................................................................................................................58

致谢 ...............................................................................................................................................69

攻读学位期间发表的学术论文 .............................................................................................70

第一章 绪论

1.1 引言

近年来,我国塑料包装行业发展日新月异,油墨的使用量逐年递增.然而,随着我国工业化逐渐朝多角度、深层次方向推进,各种的环境问题、食品安全问题也相继显现[1]."食品安全事件"频频发生,不仅对公众健康造成了极大的危害,还引发了社会诚信危机,成为社会关注的焦点问题[2].油墨是一种重要的食品包 装上的印刷材料,与人们生活息息相关.目前,我国包装行业大部分使用以氯化聚丙烯为主的苯溶性的溶剂型油墨[3].在溶剂型油墨的合成和使用过程中,挥发性有机化合物(VOCs)会引起健康、食品安全、空气污染和运输安全等一系列问题[4].随着环保法规的修订,一些溶剂型油墨已被限制用于食品包装和儿童玩具行业[5].

为了适应时代发展需要,印刷行业环保转型势在必行.由于全球挥发性有机化合物(VOCs)排放到大气中的总量受到限制,环保产品在工业生产中越来越受到人们的欢迎[6].低挥发性有机化合物技术在工业上所占的份额逐年递增.在这些低挥发性有机化合物的产品和技术中,水是合成和生产化工产品的最佳介质.事实上,水被认为是一种廉价、安全、无毒、环保的溶剂,它可以提高各种有机反应的速度和效率[7].水性油墨简称水墨,以水为主要溶剂、水性树脂、颜料和各种添加剂经分散、研磨后制成的环保型油墨.溶剂是溶剂型油墨和水性油墨的最大区别.水性油墨以水(总质量的 45%~50%)为溶剂,基本上不含或只含少量有机溶剂,大大减少了环境负担,改善了操作人员的环境,同时具有不可燃、无毒性、无异味等特点,特别适用于食品卫生工业、儿童玩具等卫生条件要求严格的包装印刷产品[8].在一些发达国家,水性油墨已经开始逐渐取代溶剂型油墨,成为生产的主要用墨[9].因此,水性油墨作为环保型油墨在印刷包装行业的使用越来越广泛.

1.2 水性油墨概述

随着人们生活水平的提高和健康意识的增强,对水性、无毒、绿色、健康产品的要求不断提高[10].水性油墨以其坏境友好的特性越来越受到人们的重视,并逐渐成为油墨工业的发展趋势.国内约 35%的软包装印刷采用水性油墨,主要采用凹版印刷[11].因此,塑料凹版水性油墨具有广阔的应用前景[12].

大约在公元前 2500 年,古埃及和中国都首次制造了书写墨水.印刷术是由中国人发明的,他们把有色泥土、煤烟和植物混合作为颜料,再把树胶作为粘合剂,最后混合两者制成墨水.而当今的印刷油墨由颜料、连接料、溶剂和各种添加剂组成.颜料使油墨展现不同的颜色并使其不透明;树脂是将油墨和薄膜粘结在一起并固定在其表面上;溶剂使油墨流动,使其能够转移到印刷表面;添加剂改变油墨的物理性质,以适应不同的情况[13].

1.2.1 水性油墨的组成

水性油墨是公认的环保型印刷无毒油墨,具有固含量高、光泽性好、流动性好等优点,被认为是最具发展潜力的油墨[14-15].水性油墨一般由连接料(载体)、着色剂、助剂(添加剂)和水组成.连接料被称为油墨的"心脏",在油墨中具有多种功能.它们能使颜料颗粒均匀分散,将颜料粘接到印刷基材上,同时作为基质树脂和油墨的成膜材料[16].

着色剂可以是颜料或染料.颜料(无机颜料和有机颜料)几乎只用于印刷工艺.它们是分散的固体,不溶于支撑材料(溶剂).染料可溶于载体材料中,与颜料相比具有耐光牢度低、耐水性差等缺点[17].

助剂用于改善油墨性能.助剂的定义是,在涂层材料的制造、储存、运输或应用过程中,为改善或修改成品涂层或涂层材料的某些性能而少量添加到涂层材料中的任何物质[18].一般来说,添加剂用于油墨配方<5%(按重量计算),以改变涂料的选定性能.通常,添加剂的含量约为油墨配方的 1.5%.添加剂包括表面活性剂、增塑剂、附着力促进剂、干燥剂、杀菌剂、消泡剂等.表面活性剂,以降低表面张力,从而解决润湿问题.增塑剂使干燥后的油墨更加灵活,干燥剂有助于氧化干燥过程.粘附促进剂或润湿剂能增强与印刷材料的结合,而杀菌剂能防止油墨的微生物降解.

作为水性油墨的溶剂,水的作用是分散连接料树脂,调整油墨的粘度,以适应不同的印刷工艺.水是一种不含挥发性有机化合物(VOCs)的溶剂,对人体、环境无害,清洗方便且能降低生产成本,符合"绿色印刷"的要求.以水为溶剂是水性油墨的精髓之处.

1.2.2 水性油墨连接料树脂的研究状况

连接料在水性油墨中起着重要作用,直接影响水性油墨的使用性能和印刷效果,如油墨黏度、光泽度、附着力、颜料颗粒分布、薄膜干燥和成型[19-21].因此,性能优良的连接料对水性油墨至关重要.连结料的发展创新决定着油墨的技术创新.目前常用的连接料树脂有水性醇酸树脂、酚醛树脂、乙烯醇、环氧树脂、聚丙烯酸树脂及改性丙烯酸乳液和聚氨酯树脂等[22].其中应用最广泛的是水性丙烯酸树脂和水性聚氨酯树脂.

1.2.2.1 水性丙烯酸树脂连接料

丙烯酸树脂主要包括水溶性型丙烯酸和乳液型丙烯酸两大类,其中水溶性丙烯酸耐水性差,一般不单独使用.丙烯酸酯树脂的涂膜具有良好的透明性、附着力、光泽度、保色性和耐候性,从而被广泛应用于水性油墨连接料[23-25].但它的耐水性差,低温变脆,高温发粘;另外,聚丙烯酸酯在塑料等非极性材料上的附着力较小,这些缺点大大限制了其发展应用[26].为了获得性能优良的聚丙烯酸酯类乳液型水性油墨连接料,研究们对其进行了大量改性研究,通过和其他乳液复配或共聚、引入功能单体共聚和交联改性等途径来改善丙烯酸乳液的性能[27].

Pi 等[28]以二异二肼(ADH)为交联剂,采用甲基丙烯酸甲酯(MMA)、丙烯酸丁酯(BA)、丙烯酸(AA)和丙烯酰胺(DAAM)作为单体,制备了一种低温自交联丙烯酸乳液.结果表明,当 DAAM 含量和 n(ADH)/n(DAAM)比值分别为 2%和 0.8:1时,该乳液的油墨膜吸水率低,对 PE 薄膜附着力好.在 PE 薄膜用水性油墨中具有良好的应用前景.

Gao 等[29]采用核壳乳液聚合法成功制备了多交联聚丙烯酸酯乳液(MCPE),特别设计了可交联的单体甲基丙烯酸(MAA)和 N-羟甲基丙烯酰胺(NMA)作为核心层单体,乙烯基三乙氧基硅烷(A151)和环氧树脂(BC2060)作为壳层单体,再加入氮吡啶(XR-100)作为交联剂.该胶膜在室温条件下经多次交联,具有良好的耐醇擦洗性能.该乳液在聚氯乙烯薄膜(PVC)用水性油墨中具有重要的应用潜力.

1.2.2.2 水性聚氨酯树脂连接料

水性聚氨酯(WPU)作为一种安全、环保、无毒的水性粘合剂,在室温下具有良好的分散性、优异的附着力、低粘度和成膜性[30-33].此外,水性聚氨酯薄膜具有耐磨性和较高的柔韧性.因此,近年来 WPU 作为水性油墨连接料树脂受到越来越多的关注.

Zhu 等[34]采用预聚体法和扩链反应分别合成了一种新型的线性和交联网络聚氨酯分散体(LWPUD 和 CWPUD).通过在 LWPUD 和 CWPUD 中加入水性着色剂、润湿剂、附着力促进剂和去离子水,得到了一种结晶度较低的新型水性油墨.交联网络型水性油墨在聚对苯二甲酸乙二醇酯(PET)基材上的附着力、耐水性和抗粘连性均优于线型水性油墨.

Lei 等[35]人比较了不同胺扩链剂和 NCO/OH 摩尔比对 WPU 性能的影响.结果表明,乙二胺(EDA)和二乙烯三胺(DETA)以 2:3 摩尔比扩链得到的 WPU 具有良好的热稳定性和粘附强度.Fang 等[36]以聚丙二醇(PPG)、异佛尔酮二异氰酸酯(IPDI)、二羟甲基丙酸(DMPA)为原料合成了结晶率低、纳米粒子分布窄的水性聚氨酯分散体(PUDs).研究表明,具有热稳定性好、酸值小、结晶度低等特点的纳米级 WPU 适合水性油墨粘结剂的使用.

1.3 水性聚氨酯概述

聚氨酯是由二异氰酸酯与多元醇(包括聚醚或/和聚酯)交替连接合成的.在反应的初始阶段,二异氰酸酯与多元醇进行加成反应,得到分子量较低的预聚体,预聚体再经扩链剂二醇或二胺等连接在一起形成高分子量的聚氨酯.通过改变多元醇的种类如软段、硬段与软段的比例、扩链剂的类型、各种功能扩链剂的比例、添加顺序等,可以调整聚氨基甲酸酯的性能[37].聚氨酯因其性能的不同,可广泛应用于粘合剂、涂料、印刷、医药等领域.然而,传统的聚氨酯是溶剂型体系,由于对减少挥发性有机化合物和有害空气污染物的要求越来越高,因此其越来越不受欢迎.而在最终乳化过程中加入水分散且可以保持数月的稳定性的 WPU,以其环保的特性受到了人们的广泛关注.WPU 具有无污染、无毒、不易燃、低温柔性好、适用性好等优异性能[38].因此,WPU 是制备新型环保材料尤其是制备水性油墨连接料的良好选择.

1.3.1 水性聚氨酯的制备方法

水性聚氨酯的制备主要分两步.首先将异氰酸酯、低聚物二元醇和扩链剂进行反应得到聚氨酯预聚体,然后将制得的预聚体在高剪切力的作用下分散于水中得到聚氨酯乳液[39].WPU 的制备根据是否需要外加乳化剂分为外乳化法和自乳化法.

1.3.1.1 外乳化法

外乳化法是通过外加乳化剂且在强剪切力的作用下将聚氨酯预聚体强制分散于水中.该方法制得的 WPU 粒径较大,稳定性差,而且外加的乳化剂用量大导致对聚氨酯成膜后的性能产生不利影响,国内外已经很少使用该方法制备水性聚氨酯[40].

1.3.1.2 自乳化法

自乳化法是指在聚氨酯预聚体分子链上引入亲水基团而不需要外加乳化剂就能使聚氨酯预聚体分散在水中形成稳定的乳液的过程.该方法制备的 WPU 粒径分布均匀,贮存稳定性好且成膜后综合性能优良,已经广泛应用于工业生产水性聚氨酯.自乳化法包括预聚体分散法、丙酮法和熔融分散法等[41].

(1)预聚体分散法

预聚体分散法是合成异氰酸酯封端的亲水性聚氨酯预聚体分子量不大、黏度较小时,不加或加少量溶剂就直接高速剪切分散于水中.该方法中链是在非均相中延伸,适用分散在水中.脂肪或脂环族二异氰酸酯制成的预聚体由于其对水的反应活性较低而被广泛应用.为了成功的应用这种方法,分散步骤必须在短时间内且在低温条件下进行.在这一过程中,必须仔细控制混合物的粘度.

(2)丙酮法

丙酮法是合成的聚氨酯预聚体黏度较大,通过添加丙酮来调节体系黏度从而使反应顺利进行的一种方法.在丙酮法中,聚合物是在均相溶液中形成的.一方面,丙酮对聚氨酯合成反应是惰性的且其是一种低沸点溶剂,在蒸馏过程中易于去除,是一种非常适合该方法的溶剂;另一方面,它通过可逆生成酮亚胺降低了异氰酸酯与胺扩链剂的高反应速率.因此,这个过程的优点包括:①重现性好,链在均质介质中延伸;②易控制预聚体和分散黏度;③最终产物是无溶剂的[42].

(3)熔融分散法

该方法是一种无溶剂合成水性聚氨酯的方法.先将异氰酸酯封端的预聚体与尿素反应形成缩二脲.然后,再将其分散在水中并与甲醛反应.最后进行缩合反应,生成聚氨酯-脲.在这种方法中,甲醛反应很难控制,还可能发生涉及聚氨酯中某些基团的副反应[43].因此,该工艺生产的水性聚氨酯应用并不广泛.

…………由于本文篇幅较长,部分内容省略,详细全文见文末附件

结论

水性油墨具有安全环保、无毒等优点,是食品包装塑料薄膜印刷油墨发展的必然趋势.而假冒伪劣是一个日益严重和长期存在的全球性问题,在我们的日常生活中也越来越普遍.本论主要是合成用于非极性包装薄膜上的新型水性聚氨酯荧光防伪油墨.本文首先讨论了两种聚酯多元醇的质量比对合成磺酸型水性聚氨酯性能的影响,然后以最佳的聚酯多元醇质量比为基础,引入荧光单体扩链剂,研究了不同荧光单体扩链剂的含量对合成水性聚氨酯的荧光性能及其他性能的影响,最后采用最佳的荧光扩链剂添加量的水性聚氨酯为连接料,以及颜料、助剂和水混合研磨制备了一系列不同颜基比的水性荧光油墨,并研究了水性油墨的相关应用性能.

本文第二章章以异佛尔酮二异氰酸酯(IPDI),聚己二酸新戊二醇酯二醇(PNA)和聚己二酸-1,4-丁二醇酯二醇(PBA)为主要原料,采用 1,4-丁二醇和乙二胺基磺酸钠(A95)为扩链剂合成了一系列水性聚氨酯乳液,研究了不同 PNA与 PBA 质量配比对聚氨酯乳液及其胶膜性能的影响.采用 FTIR 测试了 WPU 的结构.结果表明,SWPU 乳液具备良好的贮存稳定性,随着多元醇中 PNA 占比的增加,SWPU 胶膜的结晶性和拉伸强度不断降低,断裂伸长率不断增加,吸水率先减小后增加,而水接触角则先增大后减小;SWPU 乳液在 BOPP 薄膜上的T-型剥离强度先增大后减小,热稳定性差别不大.当 PNA 占多元醇的质量分数为 40%时,SWPU 的综合性能最佳,此时,SWPU 的 T-型剥离强度为 5.0N/25mm,24h 吸水率为 3.95%,水接触角为 75°,拉伸强度和断裂伸长率分别为 33.89MPa和 737.8%.

本文第三章章以聚己二酸新戊二醇酯二醇(PNA)和聚己二酸-1,4-丁二醇酯二醇(PBA)为混合软段,通过改变功能性荧光扩链剂 N,N-二羟乙基苯胺-γ-三联吡啶(TPPDA)的含量合成了一系列磺酸型水性荧光聚氨酯乳液,并采用FTIR 测试了 FWPU 的结构.结果表明,FWPU 乳液具备良好贮存稳定性,随着 TPPDA 含量的增加,FWPU 的拉伸强度不断增加,而断裂伸长率、24h 吸水率和结晶性能不断减小,T-型剥离强度和热稳定性差别不大.光学性能测试结果表明,荧光单体 TPPDA 的紫外最大吸收峰相较于 FWPU 的紫外最大吸收峰蓝移约 10nm,随着 TPPDA 含量的增加 FWPU 的荧光强度先增加后减小.当 TPPDA质量分数为 0.4%时,FWPU 胶膜荧光强度达到最大,此时,FWPU 的 T-型剥离强度为 4.8N/25mm,24h 吸水率为 3.11%,拉伸强度和断裂伸长率分为 41.73MPa和 682.4%,水性聚氨酯综合性能最佳.

本文第四章以磺酸盐型水性荧光聚氨酯为油墨连接料,以及颜料、助剂和水混合研磨制备了一系列不同颜基比的水性荧光油墨,制备出一种用于塑料包装薄膜上的磺酸型水性荧光聚氨酯防伪油墨.实验结果表明,水性荧光油墨的细度、粒径、黏度和初干性都随着颜基比的增加而增加,而光泽度则随之减小.附着牢度和耐水性随颜基比增加呈现不断变差的趋势,水性荧光油墨普遍具有较好的抗黏连性.当颜基比为 1∶2 时,水性荧光油墨(WFI2)的综合性能最优,油墨的粘度为 217.6 mPa·s,光泽度 28.6% ,细度和粒径分别为 10μm 和 14.12nm,初干性 19mm/30s,同时油墨具有较好的耐水性、附着牢度、抗黏连性和荧光强度.

参考文献

[1]樊家驹. 聚氨酯油墨与软包装印刷[J]. 中国包装工业, 2015, (17): 14-16.

[2]Chen H, Li N, Pi Y, et al. Preparation of a water-based antibacterial ink based onmicrocapsules[C]//IOP Conference Series: Materials Science and Engineering. IOPPublishing, 2019, 49.

[3]赫长生. 小议聚氨酯油墨用树脂[J]. 塑料包装, 2010, (4): 40-42.

[4]Fang C, Zhou X, Yu Q, et al. Synthesis and characterization of low crystallinewaterborne polyurethane for potential application in water-based ink binder[J].Progress in Organic Coatings, 2014, 77(1): 61-71.

[5]王正祥, 刘奇龙, 袁吉童, 等. BOPP 薄膜用水性聚氨酯油墨连结料的合成与性能研究[J]. 中国印刷与包装研究, 2013, 5(6): 13-19.

[6]Noreen A, Zia K M, Zuber M, et al. Recent trends in environmentally friendlywaterborne polyurethane coatings: A review[J]. Korean Journal of ChemicalEngineering, 2016, 33(2): 388-400.

[7]Zhou X, Li Y, Fang C, et al. Recent advances in synthesis of waterbornepolyurethane and their application in water-based ink: a review[J]. Journal ofMaterials Science & Technology, 2015, 31(7): 708-722.

[8]方长青, 张茂荣, 任鹏刚, 等. 聚氨酯基水性油墨的研究[J]. 包装工程, 2009,30(4): 45-47.

[9]黄汝权.软包装用耐温水性凹版油墨的研究[J].广东印刷, 2019(05): 38-40.

[10]Karlsson P M, Baeza A, Palmqvist A E C, et al. Surfactant inhibition ofaluminium pigments for waterborne printing inks[J]. Corrosion science, 2008, 50(8):2282-2287.

[11] Sun W, Du Y, Li X, et al. Study on Storage Stability of Waterborne Gravure Inkand Adhesion on PET/BOPP Film Surface[M]//Advances in Graphic Communication,Printing and Packaging. Springer, Singapore, 2019: 800-805.

[12]Jingxiang X, Jinyao L, Haichao L, et al. Research Progress on Water-based Ink Drying Technology[C]//IOP Conference Series: Materials Science and Engineering.IOP Publishing, 2019, 565(1): 012017.

[13]Saad E S, Nasser A M, Abd El-Wahab H, et al. Effect of different surfactantmonomers on alkali soluble emulsion polymer as a binder for water based printinginks[J]. Egyptian Journal of Chemistry, 2019, 62(1): 63-760(2): 022043.

[14]Parvez K, Worsley R, Alieva A, et al. Water-based and inkjet printable inks madeby electrochemically exfoliated graphene[J]. Carbon, 2019, 149: 213-221.

[15]王小芳, 李昭, 孙建明. 环保水性油墨制备技术与应用现状分析[J]. 科学技术与工程, 2017, 17(15): 167-175.

[16]Zhou X, Fang C, Li Y, et al. Preparation and characterization of Fe3O4-CNTsmagnetic nanocomposites for potential application in functional magnetic printingink[J]. Composites Part B: Engineering, 2016, 89: 295-302.

[17]Robert T. "Green ink in all colors"-Printing ink from renewable resources[J].Progress in Organic Coatings, 2015, 78: 287-292.

[18]Lee S, Webb S L, Webster G A, et al. Additives for ink-jet inks: U.S. Patent6,592,657[P]. 2003-7-15.

[19]刘凯.聚氨酯材料在油墨工业中的应用[J].聚氨酯工业, 1994(02): 3-7.

[20]刘培义, 曾庆景, 王金能. 水性油墨研究进展及其在封边条中的应用[J]. 广东化工, 2018, 45(21): 66-67.

[21]袁吉童. 桐油改性水性聚氨酯及其在油墨中的应用研究[D]. 2015.

[22]牛倩倩, 刘昕. 水性油墨常用连结料性能[J]. 今日印刷, 2017(3): 61-62.

[23]Mehravar S, Ballard N, Tomovska R, et al. Polyurethane/Acrylic HybridWaterborne Dispersions: Synthesis, Properties and Applications[J]. Industrial &Engineering Chemistry Research, 2019.

[24]He Y, Boluk Y, Pan J, et al. Corrosion protective properties of cellulosenanocrystals reinforced waterborne acrylate-based composite coating[J]. CorrosionScience, 2019, 155: 186-194.

[25] Guo S, Wang D, Shi J, et al. Study on waterborne acrylate coatings modified withbiomass silicon[J]. Progress in Organic Coatings, 2019, 135: 601-607.

[26]Duan Y, Huo Y, Duan L. Preparation of acrylic resins modified with epoxy resins and their behaviors as binders of waterborne printing ink on plastic film[J]. Colloidsand surfaces a: physicochemical and engineering aspects, 2017, 535: 225-231..

[27]雷亮. 塑料薄膜印刷用水性聚氨酯油墨连接料的制备及性能研究[D]. 2015.

[28]Pi P, Wang W, Wen X, et al. Synthesis and characterization of low-temperatureself-crosslinkable acrylic emulsion for PE film ink[J]. Progress in Organic coatings,2015, 81: 66-71.

[29]Gao G, Luo G, Xu M, et al. Synthesis and characterization ofmultiple-crosslinkable polyacrylate emulsion for PVC film ink[J]. Progress in OrganicCoatings, 2020, 138: 105190.

[30]Wang S, Du X, Jiang Y, et al. Synergetic enhancement of mechanical andfire-resistance performance of waterborne polyurethane by introducing two kinds ofphosphorus-nitrogen flame retardant[J]. Journal of colloid and interface science, 2019,537: 197-205.

[31]Feng J, Lu Q, Tan W, et al. The influence of the NCO/OH ratio and the 1,6-hexanediol/dimethylol propionic acid molar ratio on the properties of waterbornepolyurethane dispersions based on 1, 5-pentamethylene diisocyanate[J]. Frontiers ofChemical Science and Engineering, 2019, 13(1): 80-89.

[32]Fuensanta M, Jofre-Reche J A, Rodríguez-Llansola F, et al. Structure andadhesion properties before and after hydrolytic ageing of polyurethane urea adhesivesmade with mixtures of waterborne polyurethane dispersions[J]. International Journalof Adhesion and Adhesives, 2018, 85: 165-176.

[33]Ghosh B, Gogoi S, Thakur S, et al. Bio-based waterborne polyurethane/carbondot nanocomposite as a surface coating material[J]. Progress in Organic Coatings,2016, 90: 324-330.

[34]Zhu J, Wu Z, Xiong D, et al. Preparation and properties of a novel lowcrystallinity cross-linked network waterborne polyurethane for water-based ink[J].Progress in Organic Coatings, 2019, 133: 161-168.

[35]Lei L, Zhong L, Lin X, et al. Synthesis and characterization of waterbornepolyurethane dispersions with different chain extenders for potential application inwaterborne ink[J]. Chemical Engineering Journal, 2014, 253: 518-525.

[36]Fang C, Zhou X, Yu Q, et al. Synthesis and characterization of low crystallinewaterborne polyurethane for potential application in water-based ink binder[J].Progress in Organic Coatings, 2014, 77(1): 61-71.

[37]Lei W, Zhou X, Fang C, et al. Eco-friendly waterborne polyurethane reinforcedwith cellulose nanocrystal from office waste paper by two different methods[J].Carbohydrate polymers, 2019, 209: 299-309.

[38]Zhang J, Ren H, Chen P, et al. Preparation and properties of waterbornepolyurethane with star-shaped hyperbranched structure[J]. Polymer, 2019: 121-131.

[39]Liu Y, Liang H Q, Li S, et al. Preparation of waterborne polyurethane with highsolid content and elasticity[J]. Journal of Polymer Research, 2019, 26(6): 146.

[40]伍胜利. 水性聚氨酯的合成与改性研究[D].合肥工业大学, 2005.

[41]许戈文,黄毅萍,熊潜生等,水性聚氨酯材料[M].化学工业出版社, 2007.

[42]Honarkar H. Waterborne polyurethanes: A review[J]. Journal of DispersionScience and Technology, 2018, 39(4): 507-516.

[43]Akindoyo J O, Beg M D H, Ghazali S, et al. Polyurethane types, synthesis andapplications-a review[J]. Rsc Advances, 2016, 6(115): 114453-114482.

[44]Han Y, Hu J, Xin Z. Facile preparation of high solid content waterbornepolyurethane and its application in leather surface finishing[J]. Progress in OrganicCoatings, 2019, 130: 8-16.

[45]Yan X, Wang L, Qian X. Effect of High-Temperature Calcined Wheat StrawPowder after Lignin Removal on Properties of Waterborne Wood Coatings[J].Coatings, 2019, 9(7): 444.

[46]Liu K, Su Z, Miao S, et al. UV-curable enzymatic antibacterial waterbornepolyurethane coating[J]. Biochemical engineering journal, 2016, 113: 107-113.

[47]Li K, Shen Y, Fei G, et al. Preparation and properties of castor oil/pentaerythritoltriacrylate-based UV curable waterborne polyurethane acrylate[J]. Progress inOrganic Coatings, 2015, 78: 146-154.

[48]Wu G, Liu D, Liu G, et al. Thermoset nanocomposites from waterborne bio-basedepoxy resin and cellulose nanowhiskers[J]. Carbohydrate polymers, 2015, 127:229-235.

[49]Wang B, Qian T, Zhang Q, et al. Heat resistance and surface properties ofpolyester resin modified with fluorosilicone[J]. Surface and Coatings Technology,2016, 304: 31-39.

[50]刘敬松, 沈一丁, 赖小娟. 丙烯酸酯改性水性聚氨酯胶黏剂的制备及性能[J].化工进展, 2010, 29(4): 699-703.

[51]Wang Y, Qiu F, Xu B, et al. Preparation, mechanical properties and surfacemorphologies of waterborne fluorinated polyurethane-acrylate[J]. Progress in OrganicCoatings, 2013, 76(5): 876-883.

[52]Xu J, Hu H. Preparation and characterization of styrene acrylate emulsion surfacesizing agent modified with rosin[J]. Journal of Applied Polymer Science, 2012, 123(1):611-616.

[53]刘信胜, 刘伟区, 石红义, 等. 有机硅丙烯酸酯改性水性聚氨酯的合成与性能[J]. 精细化工, 2019, 36(6) : 1241-1248..

[54]Lin R, Zhang Y, Li H, et al. Tailoring the morphology and properties ofwaterborne polyurethanes by incorporation of acrylic monomers[J]. Progress inOrganic Coatings, 2019, 135: 65-73.

[55]张洪礼, 王文君, 黄毅萍, 等. 丙烯酸酯改性交联型水性聚氨酯胶黏剂[J]. 精细化工, 2019, 36(9) : 1962-1967.

[56]Xu C, OuYang L, Cai Z, et al. Effects of polyaminosiloxane on the structure andproperties of modified waterborne polyurethane[J]. Journal of Applied PolymerScience, 2019, 136(12): 47226.

[57]徐成书, 同晓妮, 苏广召, 等. 水性聚氨酯的有机硅改性研究进展[J]. 印染,2018 , 44(12): 52-55.

[58]Li Q, Guo L, Qiu T, et al. Synthesis of waterborne polyurethane containingalkoxysilane side groups and the properties of the hybrid coating films[J]. AppliedSurface Science, 2016, 377: 66-74.

[59]Yu Q, Pan P, Du Z, et al. The study of cationic waterborne polyurethanesmodified by two different forms of polydimethylsiloxane[J]. RSC advances, 2019,9(14): 7795-7802.

[60]Wei S, Meng L, Liu W, et al. Polyhedral Oligomeric Silsesquioxane (POSS) asReinforcing Agent for Waterborne Polyurethane Coatings on Wood[J]. MaterialsResearch, 2019, 22(2).

[61]Yang W, Du X, Du Z, et al. Effect of crosslinking on the surface free energy andsurface reorganization of waterborne fluorinated polyurethane[J]. Journal of AppliedPolymer Science, 2019, 136(10): 47167.

[62]郑桂凯, 陆明, 芮小平. 有机氟, 硅改性水性聚氨酯的研究进展[J]. 涂料工业,2018, 48(7): 79-087.

[63]Wen J, Sun Z, Fan H, et al. Synthesis and characterization of a novel fluorinatedwaterborne polyurethane[J]. Progress in Organic Coatings, 2019, 131: 291-300.

[64]Chen M, Ou B, Guo Y, et al. Preparation of an environmentally friendlyantifouling degradable polyurethane coating material based on medium-lengthfluorinated diols[J]. Journal of Macromolecular Science, Part A, 2018, 55(6):483-488.

[65]Deng Z, Ye D, Huang H, et al. Study on synthesis of water-borne polyurethanemodified by epoxy resin[J]. Journal of Functional Materials, 2007, 38(7): 1132.

[66]Zhang J, Huang H, Ma J, et al. Preparation and Properties of Corrosion ResistantCoatings from Waterborne Polyurethane Modified Epoxy Emulsion[J]. Frontiers inMaterials, 2019, 6: 185.

[67]Zhan B, Li Q S, Hong W, et al. Preparation and properties of epoxy resinmodified waterborne polyurethane[C]//Applied Mechanics and Materials. Trans TechPublications, 2013, 320: 607-610.

[68]王寅, 傅和青, 颜财彬, 等. 纳米材料改性水性聚氨酯研究进展[J]. 化工进展,2015, 34(2): 463-469.

[69]王少飞,翁雨晴,杜金梅,王鸿博,许长海.水性聚氨酯改性研究进展[J].纺织导报,2018(08): 67-73.

[70]Zhang P, Lu Y, Fan M, et al. Modified cellulose nanocrystals enhancement tomechanical properties and water resistance of vegetable oil‐based waterbornepolyurethane[J]. Journal of Applied Polymer Science, 2019: 48228.

[71]Mirmohseni A, Azizi M, Dorraji M S S. Facile synthesis of copper/reduced singlelayer graphene oxide as a multifunctional nanohybrid for simultaneous enhancementof antibacterial and antistatic properties of waterborne polyurethane coating[J].Progress in Organic Coatings, 2019, 131: 322-332.

[72]Wang L, Shen Y, Lai X, et al. Synthesis and properties of crosslinked waterbornepolyurethane[J]. Journal of polymer research, 2011, 18(3): 469-476.

[73]Yu F, Cao L, Meng Z, et al. Crosslinked waterborne polyurethane with highwaterproof performance[J]. Polymer Chemistry, 2016, 7(23): 3913-3922.

[74]康平平, 宋文生, 回金楷, 等. 磺酸型水性聚氨酯分散液的合成与性能[J]. 涂料工业, 2010, 40(8): 52-55.

[75]周亭亭. 磺酸型水性聚氨酯的制备及其性能研究[D]. 安徽大学, 2012.

[76]盛松松. 磺酸型水性聚氨酯的合成、改性及其在水性油墨中的应用[D].江南大学, 2016.

[77]宁蕾, 夏正斌, 彭文奇, 等. 磺酸盐型水性聚氨酯的研究进展[J]. 涂料工业,2010, 40(11): 71-75.

[78]徐绍娟. 磺酸型水性聚氨酯的合成与性能研究[D]. 合肥工业大学, 2013.

[79]Yang Z, Zang H, Wu G. Study of solvent-free sulfonated waterborne polyurethaneas an advanced leather finishing material[J]. Journal of Polymer Research, 2019,26(9): 213.

[80]Honarkar H, Barmar M, Barikani M. New sulfonated waterborne polyurethanedispersions: preparation and characterization[J]. Journal of Dispersion Science andTechnology, 2016, 37(8): 1219-1225.

[81]刘新浩, 李敏灵, 吕婕, 等. TMPMH 扩链剂合成磺酸型水性聚氨酯的性能研究[J]. 聚氨酯工业, 2017, 32(1): 19-22.

[82]Xia J, Xu Y, Gong C, et al. Design strategy for waterborne polyurethane withsodium sulfonate groups on the soft segments[J]. Journal of Applied Polymer Science,2014, 131(1): 39657-39663.

[83]钟震, 吴小剑, 任天斌. 原位还原制备磺酸型水性聚氨酯/纳米银复合材料及其表征[J]. 高分子材料科学与工程, 2018, 34(5): 10-16.

[84]王怀伟. 基于咔唑及其衍生物的荧光水性聚氨酯的合成及性能研究[D]. 2015.

[85]Qiang T, Han M, Li X. Synthesis, characterization and fluorescence performanceof a novel SAF-based waterborne polyurethane[J]. Progress in Organic Coatings,2018, 122: 248-254.

[86]Yang H Y, Zhang X M, Duan L J, et al. Synthesis and characterization offluorescent PEG-polyurethane with free carboxyl groups[J]. Journal of PolymerResearch, 2012, 19(9): 9973.

[87]郭雪梨. 水性聚氨酯树脂的合成及其在荧光防伪油墨中的应用研究[D]. 湖南工业大学, 2007.

[88]Pilehkouhi M, Shaki H, Khosravi A, et al. Synthesis and Characterization of aFluorescent Water-Borne Polyurethane Based on a Novel Naphthalimide Dye[J].Journal of Macromolecular Science, Part B, 2018, 57(2): 151-167.

[89]Jin Q, Hu Y, Shen J, et al. A novel 1, 8-naphthalimide green fluorescent dye andits corresponding intrinsically fluorescent polyurethane latexes[J]. Journal of CoatingsTechnology and Research, 2017, 14(3): 571-582.

[90]Yang H Y, Zhang X M, Duan L J, et al. Environmental pH‐responsivefluorescent PEG‐polyurethane for potential optical imaging[J]. Journal of AppliedPolymer Science, 2013, 129(2): 846-852.

[91]Hu X, Zhang X, Liu J, et al. Synthesis, characterization and fluorescenceperformance of a waterborne polyurethane‐based fluorescent dye 4‐amino‐N‐cyclohexyl‐1, 8‐naphthalimide, WPU‐ACN[J]. Polymer International, 2014,63(3): 453-458.

[92]Hu X H, Zhang X Y, Dai J B. Synthesis and fluorescence enhancement behaviorof a novel fluorescent aqueous polyurethane emulsion DDAQ-TDI-PU[J]. ChineseChemical Letters, 2012, 23(7): 855-858.

[93]Wang H, Zhang X, Li J. Structure and Fluorescent Performance of WaterbornePolyurethane‐Acrylate Based on a Carbazole Derivative[J]. Advances in PolymerTechnology, 2018, 37(2): 498-503.

[94]Ji X, Zhang W, Ge F, et al. Thermochromic behavior analysis of terminatedpolyurethane functionalized with rhodamine B derivative[J]. Progress in OrganicCoatings, 2019, 131: 111-118.

[95]Lligadas G, Ronda J C, Galia M, et al. Renewable polymeric materials fromvegetable oils: a perspective[J]. Materials today, 2013, 16(9): 337-343.

[96]Wu D, Qiu F, Xu H, et al. Preparation, characterization, and properties ofenvironmentally friendly waterborne poly (urethane acrylate)/silica hybrids[J].Journal of Applied Polymer Science, 2011, 119(3): 1683-1695.

[97]袁爱宁.聚醚磺酸盐型水性聚氨酯的制备、改性及应用研究[D].安徽大学,2019.

[98]王正祥,刘奇龙,袁吉童,肖细梅,陈洪.BOPP 薄膜用水性聚氨酯油墨连结料的合成与性能研究[J].中国印刷与包装研究, 2013, 5(06): 13-19.

[99]雷亮,夏正斌,杨涛,钟理.水性聚氨酯油墨连接料的关键性能分析[J].中国胶粘剂, 2015, 24(07): 54-58.

[100]顾丽争.水性聚氨酯的合成、改性及其在印刷油墨中的应用研究[D].湖南工业大学, 2012.

[101]王建龙,王正祥.混合聚酯型水性聚氨酯油墨连接料的制备及性能研究[J].粘 接, 2013, 34(08): 53-55.

[102]Xia J, Xu Y, Gong C, et al. Design strategy for waterborne polyurethane withsodium sulfonate groups on the soft segments[J]. Journal of Applied Polymer Science,2014, 131(1): 39657-39663.

[103]Patel R H, Patel K S. Synthesis of flame retardant polyester-urethanes and theirapplications in nanoclay composites and coatings [J]. Polymer International, 2014,63(3): 529-536.

[104]Niu X, Nie Z, Wang G. Preparation, flame retardancy, and thermal andmechanical properties of polyurethane containing phosphonated bisphenol-A units[J].Fire and Materials, 2018, 42(8): 933-945.

[105]Cao G, Xia Z, Lei L, et al. Crystallinity evolution of soft segments during thesynthesis of polyester ‐ based waterborne polyurethane[J]. Journal of AppliedPolymer Science, 2014, 131(10).

[106]Liu H, Li C, Sun X S. Soy-oil-based waterborne polyurethane improved wetstrength of soy protein adhesives on wood[J]. International Journal of Adhesion andAdhesives, 2017, 73: 66-74.